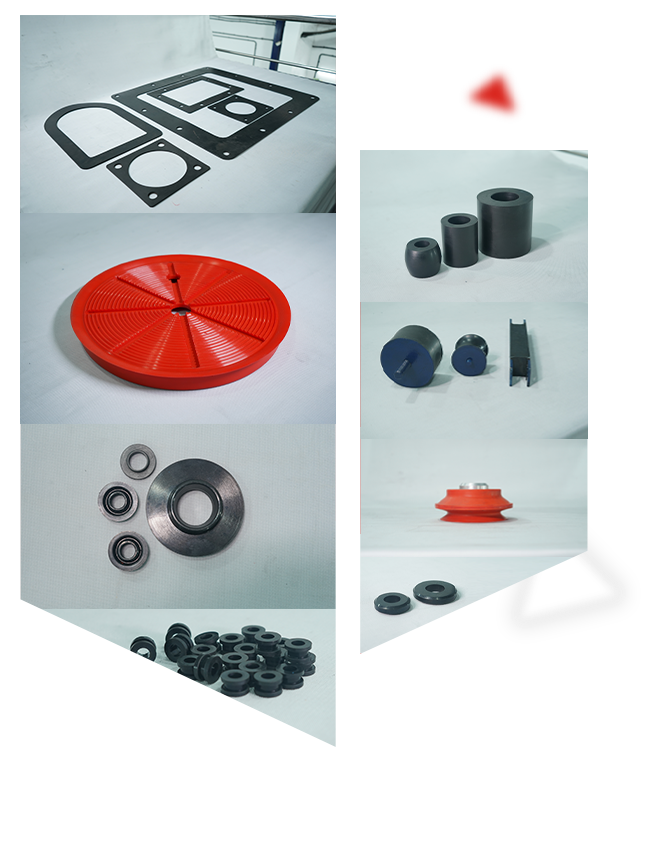

Simplex Rubbers Industries, established in 2001 is ISO 9001:2015 certified company, which excels in custom rubber solutions for diverse industries. Our expertise ensures top-quality, reliable products tailored to your needs.

We prioritize quality and innovation, delivering exceptional rubber components. Trust us for unmatched performance and lasting partnerships.

More About Us

Simplex Rubbers Industries delivers top-quality, customized rubber solutions with unmatched expertise and commitment to excellence.

Over 20 years of specialized experience in rubber components manufacturing.

Tailored solutions to meet unique industry needs.

Rigorous testing ensures superior product performance.

Continual development of advanced rubber technologies.

Products for industries from railways, power plants, heavy machineries to medical equipments.

Consistent delivery of durable and reliable rubber components.

Collaborative approach to understand and meet client requirements.

Dedicated to surpassing expectations with every solution.

Our Tensile Testing Machine is essential for evaluating the mechanical properties of rubber components. It accurately measures tensile strength, elongation, and tear strength, ensuring that each product meets our stringent quality standards. This precision testing guarantees the durability and reliability of our rubber components across various applications.

Our Abrasion Testing Machine is designed to assess the resistance to wear and tear of rubber components. By measuring the abrasion resistance and abrasion index, we ensure that our products can withstand rigorous use and maintain their performance over time. This testing is crucial for guaranteeing the longevity and durability of our rubber components in various applications.

Our advanced Oven is utilized for the post-curing of rubber components and to evaluate their compression set. This process ensures that our products achieve optimal performance characteristics, enhancing their durability and resilience. Through precise temperature control, we guarantee the highest quality and reliability in our rubber components for various industrial applications.

Our Muffle Furnace is a critical tool for determining the ash content of rubber components. This high-temperature furnace ensures accurate measurement, helping us maintain stringent quality standards. By analyzing the ash content, we guarantee the purity and performance of our rubber products across a wide range of applications.

Our Rheometer is essential for analyzing the curing characteristics of various rubber compounds. By precisely measuring the rheological properties, we ensure optimal processing and performance of our products. This advanced testing enables us to maintain consistent quality and reliability in our rubber components for diverse industrial applications.

We also conduct a range of other critical tests, including Shore A Hardness, Resilience, and Specific Gravity, to ensure the highest standards of quality and performance in our rubber components.

© Copyrights Reserved By Simplex Rubbers Industries | Design By Sai Enterprises